Solutions for Sustainable Innovation.

Learn how to leverage digital twins to reduce your project's carbon footprint.

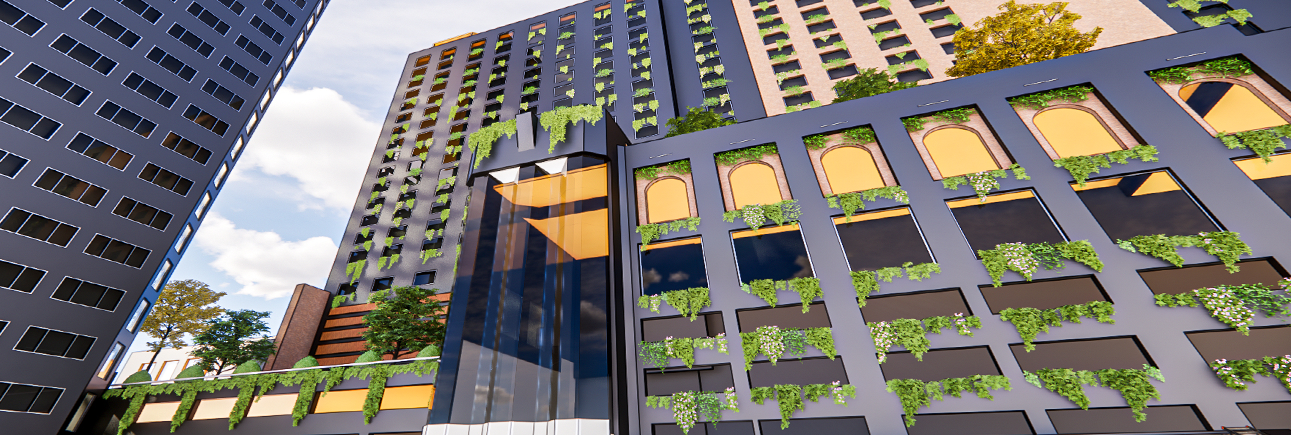

GREEN CONSTRUCTION

Building a sustainable future.

Recognizing the profound impact of construction on environmental sustainability is imperative to the overall well-being of our planet. The choices made during the construction process today will play a crucial role in shaping a sustainable future for generations to come.

By adopting green building practices, minimizing carbon footprints, and prioritizing renewable energy and materials, the construction industry can evolve into a proactive force for positive change.

TRANSFORMATIVE SYNERGY

Smart construction for a green tomorrow.

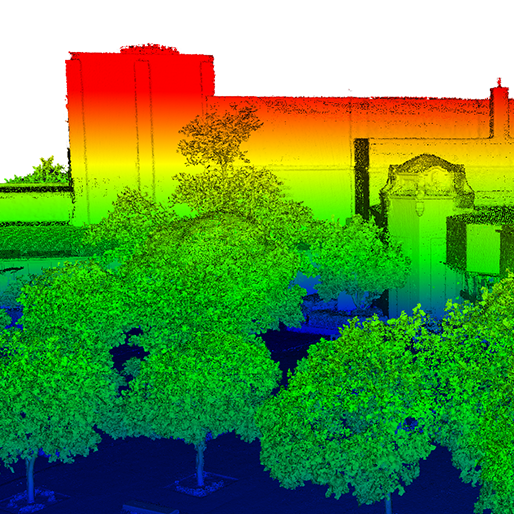

The integration of digital twins and BIM modeling has emerged as a powerful catalyst for climate change friendly building practices. These models can streamline the construction cycle which promotes efficiency and minimizes waste.

This allows organizations to make informed decisions to reduce their project's carbon footprint and create environmentally conscious structures that align with the principles of sustainable development.

TECHNOLOGY SOLUTIONS

Applying eco-friendly processes to your projects.

ZELUS® offers services in collaboration with environmental data and solution consultants to support our client's sustainable development goals and KPIs in a variety of ways.

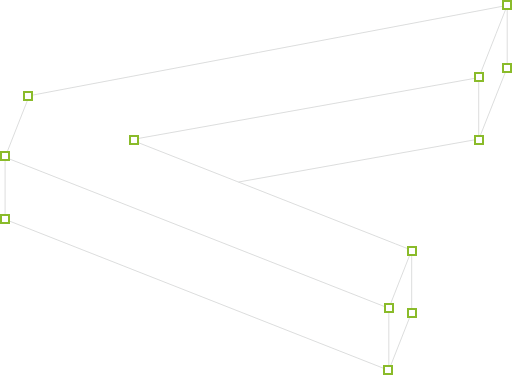

DIGITAL TWIN CREATION

Digital twins facilitate real-time monitoring and analysis of energy consumption, water usage, and other critical parameters. They also minimize construction errors which reduces material waste during the build process.

PREFABRICATION ASSISTANCE

Prefabrication allows for precise manufacturing of components in a controlled, energy efficient environment as opposed to on-site construction where tools and equipment need to be transported and operated.

4D SEQUENCING

By integrating time into the modeling process, 4D sequencing optimizes resource management including the use of construction materials, equipment, and labor resulting in reduced waste and project carbon footprint.

5D SEQUENCING

Precise materials estimating ensures that construction projects order the exact amount of materials needed. This prevents overordering and the environmental impact of excess material disposal.

DIGITAL TWIN CREATION

Digital twins facilitate real-time monitoring and analysis of energy consumption, water usage, and other critical parameters. They also minimize construction errors which reduces material waste during the build process.

PREFABRICATION ASSISTANCE

Prefabrication allows for precise manufacturing of components in a controlled, energy efficient environment as opposed to on-site construction where tools and equipment need to be transported and operated.

4D SEQUENCING

By integrating time into the modeling process, 4D sequencing optimizes resource management including the use of construction materials, equipment, and labor resulting in reduced waste and project carbon footprint.

5D SEQUENCING

Precise materials estimating ensures that construction projects order the exact amount of materials needed. This prevents overordering and the environmental impact of excess material disposal.

ENVIRONMENTAL SOCIAL & GOVERNANCE

Construct responsibly with ESG.

Global stakeholder and investors emphasize strong ESG performance now more than ever. ZELUS® is committed to supporting our client's ESG benchmarks by assisting with the 'E' or 'environmental' factor.

We monitor your digital twin to ensure environmental benchmarks and sustainability strategies are being met based on client established metrics and facility type.